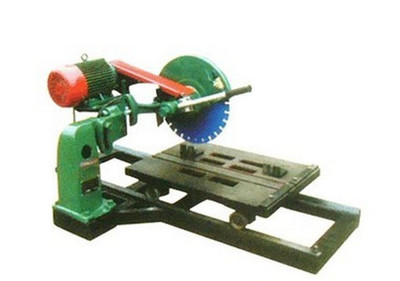

The stone carving machine does not clean in time

Stone carving machine in normal use should always clean up the impurities, grease lubrication, or relief carving machine screw in the long run, guide rail, bearing internal will have quite a lot of dust impurities into the screw. The bearing rotational resistance is large, and the speed of the carving will be slightly faster and the displacement of the bearings will be dislocated.

Technical personnel in the process of after-sale and inspection, found that many people believe that used woodworking engraving machine Stone carving machine don't have to clean the clean, also can say the basic need not tube, use the appropriate time in clean the table went, why? Because they all think woodworking engraving machine working process itself is a lot of dust, that is to say what he is applied in the dust, if every day to clean up, it would be much trouble, so a lot of people not only it is not clear, and let the machine is filled with things, this kind of practice is wrong, the correct approach is:

The end of the work should be cleared immediately, which will be convenient for the next job.

Remove the material debris next to the guide and rail to prevent the machine from being stuck in the process.

3, regular cleaning Stone carving machine, with foreign body to prevent the screw, screw in the equipment is very important, he decided that the precision of the machine, and screw also play an important role in the transmission process.

4, clean up the work control box regularly, the biggest killer of circuit boards in dust.

Woodworking engraving machine, carving machine guide rail processing center, which it maintenance method is: the requirements for the homework finished in each of X, Y, Z axis to clean the guide rails, and to clean up all the chip on the tracks and dirt, followed by check whether there is any scratch on guideway damage, clean finished to add lubricating oil to guide rail, the convenient on the second day's homework. Extending the life of the carving machine is the first step.

The method of maintenance of Stone carving machine is common: because the Stone carving machine often USES water, so the machine is relatively wet, must maintain the orbit every day. It is important to be aware of the maintenance of the oil in the X, Y and Z shafts. Be sure to use high speed butter in the screw part; If working environment temperature is too low in winter screw, polished rod, square guide or circular guide part should use gasoline to wash clean first, and then add oil, otherwise it will cause the machine drive part of the resistance is too large and cause the emergence of the problem such as dislocation.

Hot Products

People who liked this story also liked