Marble the correct maintenance method (2)

Try to figure out the general method of the Marble processing skills:

As a consumer, we must first exclude the "almost" point of view. Second, to overcome the rough look at the "sloppy". As long as you pay attention to the details of natural stone countertops, the formation of the impression, to compare, you can distinguish between seven or eight:

The first part: after the file water, that is, with the wall intersection of "after the file water", whether natural? Is the curvature round and delicate?

The second part: the stage basin, milling edge is uniform, whether the edge is equal and symmetrical, sink is centered, not biased?

The third part: the yin and yang angle is particularly reinforced, behind the table, whether there is "the same material to form the tension of the ribs."

Natural stone countertops everyone will do, different processes, different methods, the installation success rate of the left, resulting in quality and value differences. Is the "cost performance" an important measure of the angle.

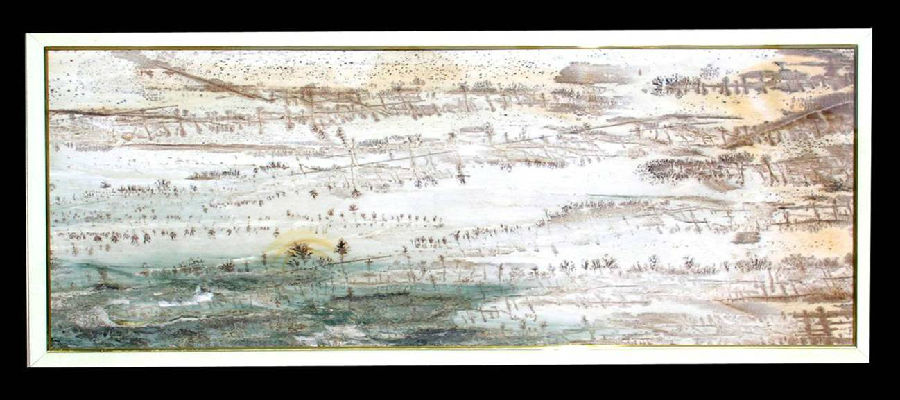

Marble countertops

Marble is actually a natural stone of a material on the difference, it is also a kind of natural stone. But because of its unique high performance cost to make it higher than the price of natural stone, is a new natural stone products. It is the natural quartz crystal ore as the main raw material, through the introduction of imported fully automated control of production technology and equipment, made in high temperature and high pressure state of the decorative panel.

Advantages: to ensure high hardness, high temperature, Naisuan Jian, impact resistance, easy to clean on the basis of any harm to the human body radioactive elements. Using the world's most advanced technology to produce ultra-hard green composite quartz plate, which contains up to 93% of natural quartz, also contains resin, mineral pigments and other additives components, selected materials by the color and vacuum high pressure to form extremely Close composite, and then by the complex cutting and surface polishing process to become marble, the surface of this plate as hard as granite, color, like a rich Marble, the structure of the same as the anti-corrosion anti-fouling glass, finishing shape Natural stone as perfect. Because of her excellent performance in many ways, making her the world's best used in the kitchen and countertop and boutique wall of the ideal material.

Disadvantages: higher prices

Special reminder: because of the Marble processing technology requirements are higher, the quality is also divided into three six nine, so in the choice of certain credibility will be better, the service has guaranteed the brand. The industry suggested that, according to cost, it is best not to consider less than 1,000 yuan of marble

Marble countertops are made from broken glass and quartz sand. Marble has the advantage of wear and tear is not afraid of scratching, heat can be a large area of paving wall, do all kinds of kitchen countertops, stitching seamless, durable.

advantage

1, scraping does not spend

Marble quartz content of up to 94%, quartz crystal is the natural hardness of diamond after the natural minerals, the surface hardness can be up to Mohs hardness of 7.5, much larger than the kitchen used in the blade and other tools, will not be scratch The

2, pollution does not dye

Marble is made under vacuum conditions in the case of a dense, non-porous composite material, the quartz surface of the kitchen, such as acid and alkali have excellent resistance to corrosion, the daily use of liquid substances will not penetrate its internal, long time on the surface Of the liquid only with water or clean and bright cleaning agent can be wiped with a rag, if necessary, can be used to scratch the surface of the blade retentive.

3, with the old

Marble bright glossy surface is after more than 30 complex polishing process, will not be blade shovel scratches, will not penetrate the liquid material, will not produce yellowing and discoloration and other issues, the daily cleaning just rinse with water Can be easy. Even after a long period of use, the surface is also the same as the new table with the bright, no maintenance and maintenance.

4, can not burn

Natural quartz crystal is a typical refractory material, the melting point of up to 1300 degrees above, 94% natural quartz made of marble completely flame retardant, will not be due to contact with high temperature and combustion, but also with natural stone and other table can not match the high temperature characteristics.

5, non-toxic without radiation

Marble surface smooth, flat and no scratches stay, dense non-porous material structure makes the bacteria nowhere to hide, can be in direct contact with food, safe non-toxic!

High-quality marble with a selection of natural quartz crystal mineral, the SiO2 content of more than 99.9% or more, and in the manufacturing process to purify, the raw material does not contain any possible lead to radiation of heavy metal impurities, 94% of the quartz crystal and other The resin additive makes the Marble free of radiation contamination.

From:Marble

Hot Products

People who liked this story also liked